What is a PLC?

PLC stands for "Programmable Logic Controller". PLC is a computer specially designed To work reliably under harsh industrial environments - such as extreme temperatures, wet, dry, and/or dusty conditions. It is used to automate industrial processes such as an assembly line of manufacturing plants, ore processing plants, or wastewater treatment plant.

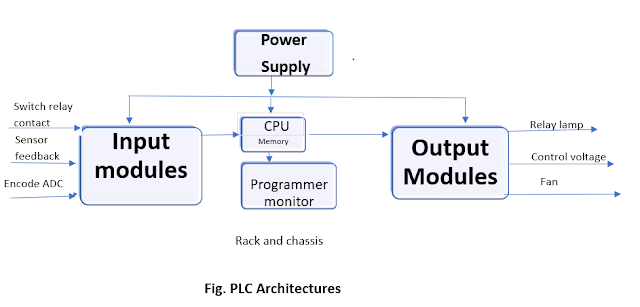

PLCs share many of the features of a personal computer that you keep at home. They both have one Power supply, a CPU (central processing unit), inputs and outputs (I / O), memory, and Operating software (although it is a separate operating software). The biggest difference That a PLC can perform discrete and continuous tasks that a PC cannot, and a PLC is largely adapted to rough industrial environments. Can be thought of as a plc. A 'rugged' a digital computer that manages one's electrical processes Industrial environment.

PLC was invented by Dick Morley in 1964. PLC has revolutionized since

then Industrial and manufacturing sectors. PLC like Time has a wide range of

functions, Computations, calculation, comparison, and processing of

various analog signals. The main advantage of PLC over

"hard-wired" control system is that you can go back And after

you change the PLC when you program it, the level cost (just the cost of the

programmer) Time). In a hard-wired control system, you essentially start by ripping

wires From scratch (which is more expensive and takes longer). Let's look

at an example Beer realizes this benefit. Imagine that you have light connected

to a switch. In general, the light operates under two Conditions - On and

Off. Now you are given a task when you turn the switch on, The light

should only glow after 30 seconds. With this hard-wired setup - we're

stuck. The only way to achieve this is to completely revive our circuit to

connect the timing relay. It is too much trouble for minor changes.

0 Comments